Digital transformation has evolved quickly from a conceptual phase to a semiconductor industry change agent. The rapid take up of AI-enhanced product development is only accelerating this transformation and is further influenced by two connected trends: The movement of Moore’s Law from transistor scaling to system-level scaling, and the relatively recent redistribution of the global electronics supply chain due to the COVID-19 pandemic.

I spoke on this subject earlier this month at the Industry Strategy Symposium 2024 in Half Moon Bay, California, where leaders from across the chip industry gather annually to share their insights on technology and trend drivers and what they could mean for our respective businesses.

Between the early 1970s and around 2005, increased chip performance was largely a function of clock frequency improvements driven by advances in lithography, transistor density, and energy efficiency. With increasing transistor counts (and die size), clock frequencies are limited by interconnect delays and not by transistor performance. To overcome this challenge, designers moved to multi-core designs to increase system performance without blowing up energy. Novel packaging techniques such as chiplets and multi-chip modules are helping further improve system performance, particularly in AI chips.

A single chip package may be comprised of multiple chiplets each housing specific functions such as high-performance logic elements, AI accelerators, high-bandwidth DDR memory, and high-speed peripherals. Very often, each of these components is sourced from a different fab, a trend that has resulted in a fragmented global supply chain. This creates its own set of challenges as die from multiple fabs must be integrated into a package or system that must then be thoroughly tested. Test failures at this stage have enormous financial consequences. These challenges, require a “shift left” mindset in product development. The shift left mentality has major ramifications for how we, as an industry, should be managing our supply chains by moving the heavy emphasis from architecture/design to final system testing and quality.

Supply chain challenges during the COVID pandemic have resulted in further decentralization of the supply chain components. To illustrate the enormity of the change underway, consider that between 2022 and December 2024 construction began on 93 wafer fabs around the world. Compare that to the global construction of automated test facilities. In 2021 alone, the industry broke ground on 484 back-end test sites, which provides a measure of how committed the chip sector is to driving resiliency across the manufacturing landscape.

The Role of AI in Semiconductor Design and Manufacture

So, where does AI come into the picture?

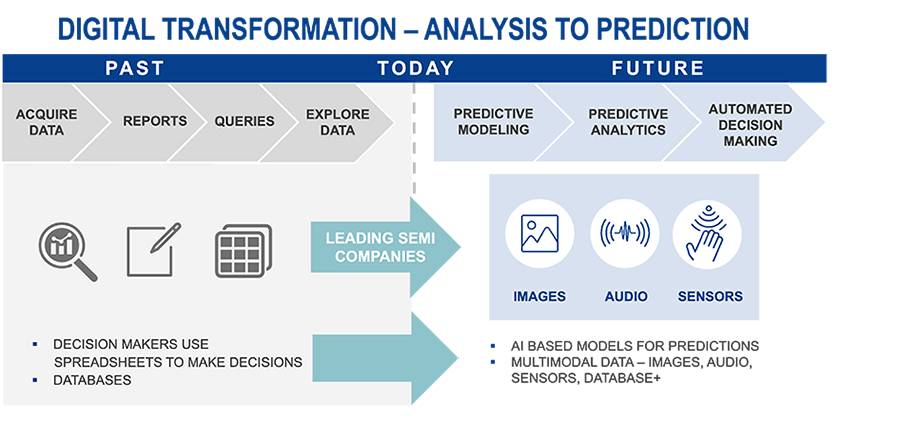

A key area in which AI will exert its influence is the shift from an analytic to a predictive model. Today, we wait to detect a problem and then look at past data to identify the root cause of the problem and prevent it from reoccurring. This inefficient approach adds time, cost, unpredictability, and waste to the supply chain. AI, on the other hand, allows us to examine current data to predict future outcomes.

Instead of using spreadsheets to analyze old data, we build AI models that production engineers continuously train with new data. This “new” data is no longer merely a set of numbers or measurements but includes unstructured data such as die photos, equipment noise, time series sensor data, and videos to make better predictions.

In the end, it’s about pulling actionable information from a sea of data points. In other words, data without action is mostly useless. Why am I driving this point home? Because today, 90 percent of data created by enterprises is never used. It's dark data. And when you think about AI implementation, 46 percent of them never make it from pilot to production because the complexity of the programs is not scoped appropriately.

Despite these challenges, equipment makers are already starting to implement digital transformation techniques into their product development processes. The benefits are palpable. Research from Boston Consulting Group found that companies that have built resiliency into their supply and design chains recovered from COVID-related downturns twice as fast as companies that have yet to embrace digital transformation.

At Renesas, we acquired a company called Reality AI that generates a compact machine learning model that runs on a microcontroller or microprocessor. This provides the unique ability to quickly detect deviations from normal patterns that may cause equipment problems. It allows manufacturing facilities to schedule preventive maintenance or minimize downtime associated with sudden equipment failure.

Digital Transformation Is Future-Proofing Our Industry

Digital transformation with AI is key to business success today. As the semiconductor industry undergoes a major evolution – embracing system-level design and adapting to a changing global supply chain – digital transformation and the shift left approach are powerful tools that deliver on two fronts.

The first is a productivity increase that comes from optimized tools and design processes. The closer you are to where the failure is likely to occur, the more quickly you learn and the more quickly you can fix things.

Second, and perhaps most importantly, digital transformation solves one of the biggest problems the industry has with chip design – the availability of talent. When we reduce the time taken to design a chip, we’re making our engineers far more efficient than they would be otherwise, which is increasingly important as the semiconductor industry demographic skews older.