Industrial automation device manufacturers are looking for reliable and easy-to-integrate solutions for their designs. They prefer support for digitalizing factory automation and creating smart, connected factories instead of separate, closed systems. IO-Link, a point-to-point communication protocol, ensures seamless communication at the field level. It is a protocol defined by IEC 61131-9 as an international standard. IO-Link connects sensors and actuators to remote I/O or PLC in factory automation. With the growth of Industrial IoT, the demand for IO-Link is increasing as it allows unified management of big data from sensors and actuators.

IO-Link is a communication protocol commonly used in industrial automation for two-way communication between sensors and actuators. It allows ”Device" devices such as sensors and actuators to communicate with "Master" devices such as PLCs using IO-Link. The connection is made through a 3-wire cable that should be up to 20 meters in length. Typically, the IO-Link Master handles both digital and analog data processing and can use various protocols like Profinet, Ethernet/IP, and Modbus. The market is divided based on type, component, application, industry vertical, and region, with wired and wireless options available. Various industries, including oil and gas, energy and power, automotive, pharmaceuticals, food and beverages, and chemicals, utilize IO-Link in applications such as machine tools, handling and assembly automation, intralogistics, and packaging.

As a market leader, Renesas provides comprehensive hardware and software solutions for IO-Link and related solutions as outlined below.

IO-Link Master Solution

Easy-to-use gateway development kit for the IO-Link protocol

Connects up to eight IO-Link sensors or actuators and supports industrial Ethernet communication controlled by the RZ/N1S, an Arm® Cortex®-A7 (See Figure 2).

- CCE4510 IO-Link Master PHY has a built-in IO-Link hardware frame handler that significantly improves application performance

- Temperature and supply voltage monitoring and protection

- Overload protection for channels and connected devices

- Optimized for up to 8-port IO-Link master applications

- Optional secure boot function

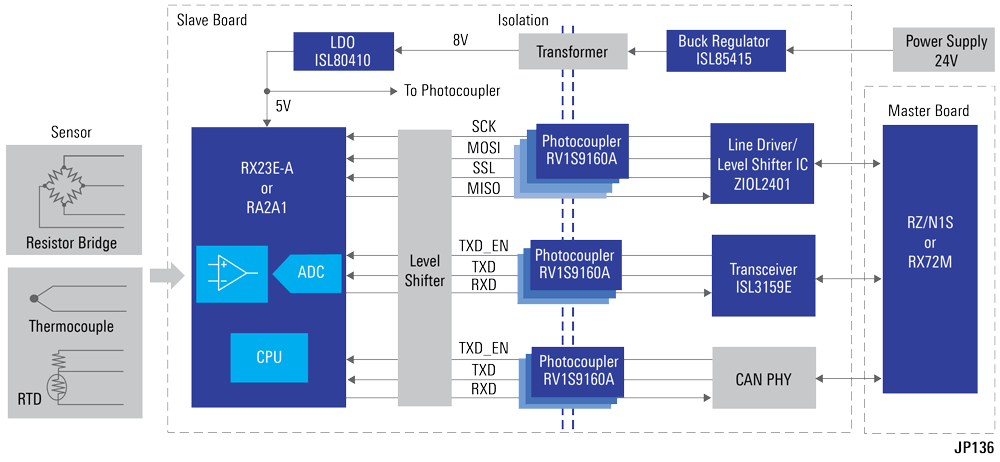

RX23E-A IO-Link Temperature Sensor Solution

Ready-to-use IO-Link bidirectional communication for temperature sensor solution

This single-chip solution has a built-in high-precision analog front-end (AFE) to measure temperature, process sensing, and signals.

- IO-Link for a temperature controller solution based on the RX23E-A 32-bit MCU on-chip high-precision analog front-end (AFE) for signal processing, and communication control via IO-Link PHY on a single chip (See Figure 4).

- Contributes to reducing investigation time at the beginning of development by providing an application note, sample program with protocol stack, BOM, and circuit diagram.

- Offers the RZ/N1S as an IO-Link master and scalable lineup for the IO-Link master and device PHY.

RA2E1 IO-Link Pressure Sensor Solution

Ultra-compact RA2E1 MCU enables miniaturization for pressure sensor application

Enables compact solutions that can be implemented in small spaces and contribute to BOM cost reduction and system miniaturization.

- RA2E1 supports an ultra-small size and package line-up (LQFP, QFN, BGA, LGA, and CSP).

- ZSSC3240 achieves high-accuracy sensor correction with up to 24-bit A/D converter resolution.

- Two types of device PHY available: CCE4503 IO-Link compliant transceiver with LDO (max. 20mA) and ZIOL2401 IO-Link line driver with buck regulator (max. 50mA) (See Figure 4).

- Provides power supply ICs and other peripheral components.

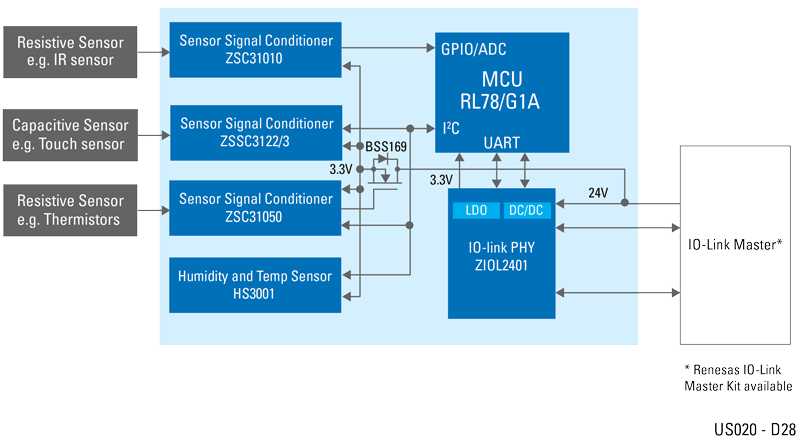

RL78 IO-Link Enabled Sensor System

Microcontrollers for simple communication functions, low power consumption operation, and measurement

Industrial automation uses IO-Link for sensor and actuator connectivity. Industrial sensing applications can use IO-Link-supported Renesas RL78 microcontrollers.

- UART and SPI hardware interfaces for IO-Link device communication enable seamless integration of sensors, actuators, and IO-Link devices into industrial automation systems (See Figure 3).

- Offers flexible and scalable options, allowing you to select an MCU that matches your industrial sensing requirements.

- Prioritize low power consumption, making them ideal for energy-efficient industrial applications.

The industrial networking arena is quite diverse including a wide range of technologies like Industrial Ethernet covering EtherCAT, Profinet, Ethernet/IP, CC-Link IE, Modbus-TCP, and OPC-UA, as well as a variety of Fieldbus options such as Profibus, Modbus RTU/ASCII, DeviceNet, CANopen, and IO-Link etc. The evolution in this dynamic field continues, making the industrial journey ahead even more interesting and exciting.

In the field of industrial automation, the need for data collection, remote management, and regular maintenance of equipment has increased significantly. The most common method of data collection is to send data to higher-level devices via one-way direct communication. The number of to-be-installed devices has multiplied, and for a wide coverage area, it increases the cost of introducing a new communication protocol to the existing wiring. Renesas as a market leader in this field provides comprehensive solutions including hardware such as MCUs, IO-Link PHY, and other related components along with an easy-to-use IO-Link device tool, enabling faster time to market.

For more information, check out our Factory Automation, Industrial Ethernet & Fieldbus, and IO-Link Device Applications.